turbo altezza, pics up

Moderator: The Mod Squad

63 posts

• Page 3 of 4 • 1, 2, 3, 4

wow

far out si thats alot of progress sinse i last saw it.

looks like its almost ready to go

looks like its almost ready to go

Curre3nt rides-

1982 starlet kp61 4 door (in panel shop getting bare metal resto)

1980 tt132 corona wagon 3t t40 (daily doomsday machine)

1982 starlet kp61 4 door (in panel shop getting bare metal resto)

1980 tt132 corona wagon 3t t40 (daily doomsday machine)

-

TOYROTA - Toyspeed Member

- Posts: 347

- Joined: Thu Jul 17, 2003 8:35 pm

- Location: HAMILTON

The pipe that comes off the wastegate, (the screamer), does that vent to atmosphere? What psi spring is in it? And when it opens when its driving, what will the motor do? Will it just halt in making power and die?

Though, very interesting

Though, very interesting

Karl Pilkington On seals - "Its between a fish and a dog."

-

samlloyd - Toyspeed Member

- Posts: 1047

- Joined: Mon Feb 21, 2005 8:01 am

- Location: Rotorua/gold coast/Bangkok

Lith wrote:I didn't pick up on the wastegate on the pressure side of the inlet setup to control boost - really doesn't sound like a good idea to me, wouldn't it be creating what is normally considered a problem? Ie, an air leak while under boost?

If the thing ever reaches enough pressure that the "wastegate" needs to be opened, then the turbos are still going to behave like they are freeboosting - but the air isn't going to go into the engine. The turbo bearings are still going to take the full brunt of potentially excessive RPM and the air will still get heated quite nicely. Airleaks are a big turbo killer....

There was a well known performance place in Aus that used to do it all the time. There was quite a write up about it on there site a while ago.

Seems that as long as the turbo's are sized accordingly, and the BOV is also sized accordingly,

it all works perfect.

My bet will be the w58 gives up before the rest.

Matt

- matt dunn

- Toyspeed Member

- Posts: 7109

- Joined: Fri Sep 12, 2003 1:01 am

- Location: Timaru

smithers wrote:The pipe that comes off the wastegate, (the screamer), does that vent to atmosphere? What psi spring is in it? And when it opens when its driving, what will the motor do? Will it just halt in making power and die?

Though, very interesting

id assume that the motor will behave exactly like if the boost control was placed on the exhaust side. The only difference between intake and exhaust boost control will be the speed the turbos are spinning at. ie. when an exhaust wastegate opens, the turbine sees less exhaust energy and thus maintains a constant speed and intake pressure. when the intake wastegate opens, the turbines will continue to build speed, but the amount of pressure the engine sees will be steady due to the excess pressure being released through the intake side.

The engine wont be able to tell the difference between these two types of boost control since it will be run using a map sensor which measures airflow using pressure in the intake manifold.

- rage

- Toyspeed Member

- Posts: 170

- Joined: Thu Jul 29, 2004 6:52 pm

matt dunn wrote:Seems that as long as the turbo's are sized accordingly, and the BOV is also sized accordingly,

it all works perfect.

My bet will be the w58 gives up before the rest.

Turbo sized accordingly meaning are essentially oversized so it will never get up to the shaft speeds where things really start becoming a problem??

I agree though, I doubt its going to be a problem - I'm assuming that a MAP sensor is being used to give information required for critical calculations. Again, the seriously huge twin turbos are going to be stopping things from getting too crazy in a big hurry - taking a quick look at T04R.Com they reckon the "useful powerband" on a 2JZGTE starts at ~5800rpm on a GT4788 which uses an 88mm inducer. A pair of T70s work out to a similar inducer area to a 98mm inducer based turbo, so there's potentially going to be a lot of boost building going on haha

Look forward to hearing how it comes out, I'd love to see it! Kudos to trying it out, definitely very different.

-

Lith - Toyspeed Member

- Posts: 3137

- Joined: Mon Dec 02, 2002 5:22 pm

- Location: Kapiti

Just give it a 250HP shot of NOS to help it spool

Current: , '96 SubaruImpreza

Previous: '92 EE80 Corolla, '91 JZZ30 Soarer(The single snail whale), '91 AE92 FXGT(Silvertop 20v), '92 JZA70 MkIIISupra (The twin snail whale), '82 MkV Cortina.

Previous: '92 EE80 Corolla, '91 JZZ30 Soarer(The single snail whale), '91 AE92 FXGT(Silvertop 20v), '92 JZA70 MkIIISupra (The twin snail whale), '82 MkV Cortina.

-

Si - Toyspeed Member

- Posts: 1304

- Joined: Wed Jan 07, 2004 10:19 pm

- Location: Wellywood

Si wrote:Just give it a 250HP shot of NOS to help it spool

...and watch the turbos shit themselves - if the gearbox hasn't already

I'm all for innovation, but this thing has all the disadvantages of a 1500hp monster (no power below 6k rpm), and only 700hp worth of fuel? Why not just use one t70? If you are planning on making use of the huge flow of those blowers (with more fuel), why not spend some money on replacing the stock intake manifold? What do you think you're achieving by running free boosting turbos? A pre-turbine wastegate will always be more efficient than a post-compressor wastegate.

Sorry man i just dont see the point

-

gmacrae - Toyspeed Member

- Posts: 1194

- Joined: Wed Nov 06, 2002 11:13 pm

- Location: Rotorua

gmacrae wrote:I'm all for innovation, but this thing has all the disadvantages of a 1500hp monster (no power below 6k rpm), and only 700hp worth of fuel? Why not just use one t70? If you are planning on making use of the huge flow of those blowers (with more fuel), why not spend some money on replacing the stock intake manifold? What do you think you're achieving by running free boosting turbos? A pre-turbine wastegate will always be more efficient than a post-compressor wastegate.

Sorry man i just dont see the pointlooks great tho.

haha y not,

we have seen similar wastegate setups done over seas so decided to try it our selves, plus the fact we dont really have room for wastgates on the exhaust side, i could fit them if i really wanted, but this will do for testing.

one t70 looked stupid in the engine bay, the basic reason we went for 2.

the stock inlet is on the agenda, i have plans to fabricate one up when i can be arsed.

as with a list of other bits, at this stage the plan is make it running and drivable,

when we get around to it a 2 more pumps will most likely be added, the surge tank im making has the facility for 2 outlets, and 2 inlets,

at the end of the day its something a lil different, makes from the norm with boring altezza's, and the turbo setup is something we wanted to try.

-

evil_si - Toyspeed Member

- Posts: 2353

- Joined: Sat Nov 01, 2003 6:19 pm

- Location: TAURANGA, Pyes Pa

Stolen from another website,

Thats a post from last year

This needs to be a pretty long explanation to fully understand ALL the reasons for and against the reasons I some times use wastes gates,blow off valves, or even some times both.

But first a little history. Back in the days of early Rb 30 development this would have been about 1988/1991 we were starting to make some really good numbers about 500 hp,and the turbo's that were available were not up to today's standard, nor were the waste gates, you could get I think from memory a 42 mm Garrett was the best we could get and it was a big bulkie thing so fitting it in the car with extractors and turbo was also difficult, this then lead to the fact that trying to get lots of flow to it was also hard.

Now the next problem was trying to hold high boost levels at high rpm above 6000, by this time the turbos were running out of puff so the waste gate was completely shut anyway,I now see this happening again at events like dyno challenge days were people are trying to get huge

hp numbers.

So the only place the waste gate was working was in the mid range, and because at that point the engine still had good V.E. we were trying not to put to much boost into them as they would break con rods above 500 foot pounds of torque. [Sound like the BA, a history making lesson for the future]Now because the waste gate were A too small and B you didn't have enough room in the engine bay to place the gate in a good flowing position the damn things would not control the boost, and they would boost spike, wammo broken engine. So the answer we came up with was to add a blow off valve or as we called it an over boost valve, that was set to a maximum pressure that would 'nt destroy the engine through to much torque.

Now all of a sudden we thought well if the waste gate was not doing its job in the mid range and it was fully close at the top end why bloody have it. So in the bin it went.

We now started to control the blow of valve electronically with the boost control output Thur the Motec and we found we had better control than ever before.

As far as over speeding the turbo goes remember two things, firstly the waste gate was fully closed at the top end anyway, and so is the blow off valve for that mater,so there is no difference at that point. Secondly the turbo is driven by exhaust gas and that gas is being created by the air entering the engine, so if you blow some of that air off it never gets to make exhaust and then never gets to spin the turbine ,hence speed is also not greatly effected.

There are also plenty off other reason why we do now use waste gates in conjunction with blow off valve but I'll get to that in another 5 years or so

Thats a post from last year

- matt dunn

- Toyspeed Member

- Posts: 7109

- Joined: Fri Sep 12, 2003 1:01 am

- Location: Timaru

matt dunn wrote:As far as over speeding the turbo goes remember two things, firstly the waste gate was fully closed at the top end anyway, and so is the blow off valve for that mater,so there is no difference at that point. Secondly the turbo is driven by exhaust gas and that gas is being created by the air entering the engine, so if you blow some of that air off it never gets to make exhaust and then never gets to spin the turbine ,hence speed is also not greatly effected.

There are also plenty off other reason why we do now use waste gates in conjunction with blow off valve but I'll get to that in another 5 years or so

Interesting, boost spike is usually a problem caused in the boost message -> wastegate setup, not the wastegate itself. If the "boost line" to the wastegate isn't well placed or the hose isn't big enough - causing a slow reaction of the wastegate, or the boost controller (ie, whatever is bleeding boost to get the wastegate to allow a higher boost level) isn't configured correctly then thats how you get a spike. Boost creep is a symptom of a badly placed or insufficiently sized wastegate - at least in my experience or understanding.

Also, I can see how one could buy the theory that if the air isn't going in - why would the turbine be spun faster if one didn't think it through or perhaps sufficiently understand how a turbo works. If you DO think it through - it has to spin THAT much faster to generate a given pressure level in a system which has a leak in it.

Overly simplified, imagine getting a balloon and partially blowing it up until you reach a particular pressure. Now you have reached full boost, see if you can create a tiny leak and keep the balloon inflated to the same amount. I bet it gets quite hard quite quickly?

For the turbo to even maintain the same boost level, it has to create a restriction out of the air leak. Depending on how hard its working to do that, half of the pressure you are reading on the boost gauge could be resulting from heat from the compressor moving out of its efficiency range - not from the head providing restriction from the air the compressor is moving. The turbo is going to be moving WAYY more air than the engine is ingesting and compressor efficiency is restricted by the air mass the compressor pumps, not what the engine actually receives. Effectively what it sounds like the pop off valve is doing is keeping the compressor spinning at its choke point - where it just can't pump any more air.

That concept is pretty bad, in my opinion - though not so likely to be a problem with the excessively oversized turbos.... though probably would explain why people used to have a lot of turbo failures in the earlier days of turbocharged drag cars. I wouldn't want that workshop near my car!!!

-

Lith - Toyspeed Member

- Posts: 3137

- Joined: Mon Dec 02, 2002 5:22 pm

- Location: Kapiti

all this stuff about how bad people think it's going to work. have you seen a setup like this?

big ups to you simon for seeing similar setups, and deciding to give it a go, and "experiment" with it. not many people would.

why not people instead of critisize it, just wait and see how it works

big ups to you simon for seeing similar setups, and deciding to give it a go, and "experiment" with it. not many people would.

why not people instead of critisize it, just wait and see how it works

Current Rides: 1994 Hiace Custom

KTM 250sx

Previous Car: 1988 Toyota Levin 4agte

234kw atw and 12.5@183kmh

Sold to a muppit who wrecked it

Hmm

KTM 250sx

Previous Car: 1988 Toyota Levin 4agte

234kw atw and 12.5@183kmh

Sold to a muppit who wrecked it

Hmm

-

IH8TEC - Toyspeed Member

- Posts: 3128

- Joined: Wed Nov 26, 2003 7:11 pm

[quote="Al"]700? Thats a bit conservative. There are 1000rwhp+ stock bottom end Supras in the US.  [/quote

[/quote

700,1000 hp I have seen these to out of Supra's in the U.S but if I was to do something like this I'd keep the power down to the 500-600 range for reliability.The HP numbers that are coming out of the U.S are inflated as there Dynojet Dyno's read about 10-15% higher than what we have here and I feel you are only hearing the final numbers not the grief it took to get these numbers...

Anyways good work with your conversion here are you using all the Supra running gear i.e diff,suspension????I think the weak point is going to be that w58 5 speed box the torque this motor is going to make will just smash that gearbox..

700,1000 hp I have seen these to out of Supra's in the U.S but if I was to do something like this I'd keep the power down to the 500-600 range for reliability.The HP numbers that are coming out of the U.S are inflated as there Dynojet Dyno's read about 10-15% higher than what we have here and I feel you are only hearing the final numbers not the grief it took to get these numbers...

Anyways good work with your conversion here are you using all the Supra running gear i.e diff,suspension????I think the weak point is going to be that w58 5 speed box the torque this motor is going to make will just smash that gearbox..

- 2jayzgte

- Toyspeed Member

- Posts: 1997

- Joined: Thu Sep 14, 2006 9:16 pm

IH8TEC wrote:big ups to you simon for seeing similar setups, and deciding to give it a go, and "experiment" with it. not many people would.

why not people instead of critisize it, just wait and see how it works

I've already said both of the above things man - I think its cool, and I think its not going to be too much of a problem with his implementation and am all for something different or crazy. I'm just making sure, for the risk of people getting the idea that its a good way of controlling boost level and blowing things up (or at least prematurely aging parts) that its by far the best way of doing things in most applications.

The basic reason it has been done by Evil Si is to control the boost level, I'm pretty sure it will do that. End of story in terms of THIS application.

-

Lith - Toyspeed Member

- Posts: 3137

- Joined: Mon Dec 02, 2002 5:22 pm

- Location: Kapiti

using a pop off valve on the intake has been used sucsessfully in motorsport for years. ie CART, F1, WSC etc

the key, as with all aspects of modifying cars is correctly matching the components.

the key, as with all aspects of modifying cars is correctly matching the components.

-

Mr Revhead - SECURITY!

- Posts: 24635

- Joined: Tue Jan 20, 2004 4:06 pm

- Location: Nelson

Good explanation Lith, hope everyone read it.

The problem i see is not so much the fact that you'll be overspinning the turbos though, because you'll be on the rev limit before they've had a decent chance to spool. It's gonna have to run very low boost to not overpower the current fuel setup (prob 15psi or so). It will have the massive lag of a 100mm turbo, all for a measly 5-600rwhp... one t70 could do this no sweat, with usable power from 4k rpm up, if it is actually a 70mm inducer.

Stock internals, stock cams, stock intake just wont be able to make use of those turbos... that said, it still looks cool lol

Edit;

You also cant compare free-boosting these turbos to the one on the old rb30 above. The turbo on the rb30 was "running out of puff" because of a its old restrictive turbine and it was being used outside of its very limited efficiency range, modern turbos have much greater efficiency and WILL keep spinning till they self-destruct... though like i said, unless a 'spool-aid' is used (nitrous, antilag) it wont be a problem in this case.

Stock jza80 (steel) turbos work quite similar, on a car with a few mods, you can run 20psi fairly safely, but at the top end they just cant spin hard enough to keep feeding the engine 20psi and your boost drops off a bit - even with the wastegate closed. Shit stock manifolds, tiny restrictive housings, ineffecient wheels etc

The problem i see is not so much the fact that you'll be overspinning the turbos though, because you'll be on the rev limit before they've had a decent chance to spool. It's gonna have to run very low boost to not overpower the current fuel setup (prob 15psi or so). It will have the massive lag of a 100mm turbo, all for a measly 5-600rwhp... one t70 could do this no sweat, with usable power from 4k rpm up, if it is actually a 70mm inducer.

Stock internals, stock cams, stock intake just wont be able to make use of those turbos... that said, it still looks cool lol

Edit;

You also cant compare free-boosting these turbos to the one on the old rb30 above. The turbo on the rb30 was "running out of puff" because of a its old restrictive turbine and it was being used outside of its very limited efficiency range, modern turbos have much greater efficiency and WILL keep spinning till they self-destruct... though like i said, unless a 'spool-aid' is used (nitrous, antilag) it wont be a problem in this case.

Stock jza80 (steel) turbos work quite similar, on a car with a few mods, you can run 20psi fairly safely, but at the top end they just cant spin hard enough to keep feeding the engine 20psi and your boost drops off a bit - even with the wastegate closed. Shit stock manifolds, tiny restrictive housings, ineffecient wheels etc

-

gmacrae - Toyspeed Member

- Posts: 1194

- Joined: Wed Nov 06, 2002 11:13 pm

- Location: Rotorua

gmacrae wrote:Good explanation Lith, hope everyone read it.

Cheers, though most people will just skim straight past it and not ingest it - and say things in response which make it obvious thats the case, such as:

Mr Revhead wrote:using a pop off valve on the intake has been used sucsessfully in motorsport for years. ie CART, F1, WSC etc

the key, as with all aspects of modifying cars is correctly matching the components.

Pop off valves are often a requirement where there is a maximum boost level, and is something easily checked to be in place and potentially a standard item for the class rules if I understand correctly. So in motorsport, I'd think of them as one of those pain in the arse things you DON'T want but have to work with as opposed to something that seems like a wonderful way of controlling boost.

You can trick a boost gauge, you can bleed the feed to a wastegate, but if you have a pop off valve on the intake you're just not going to run more boost than the pop off valve will allow unless you are REALLY cunning (go Honda hahahaha). A lot of F1 cars used a wastegate despite the pop off valve.

The setup Matt Dunn quoted Nizpro having with their pop off valve setup is CLEAR evidence of people who don't know how to or have the parts to correctly match up the components - otherwise they would have never needed the popoff valve as the wastegate would have been controlling boost fine!

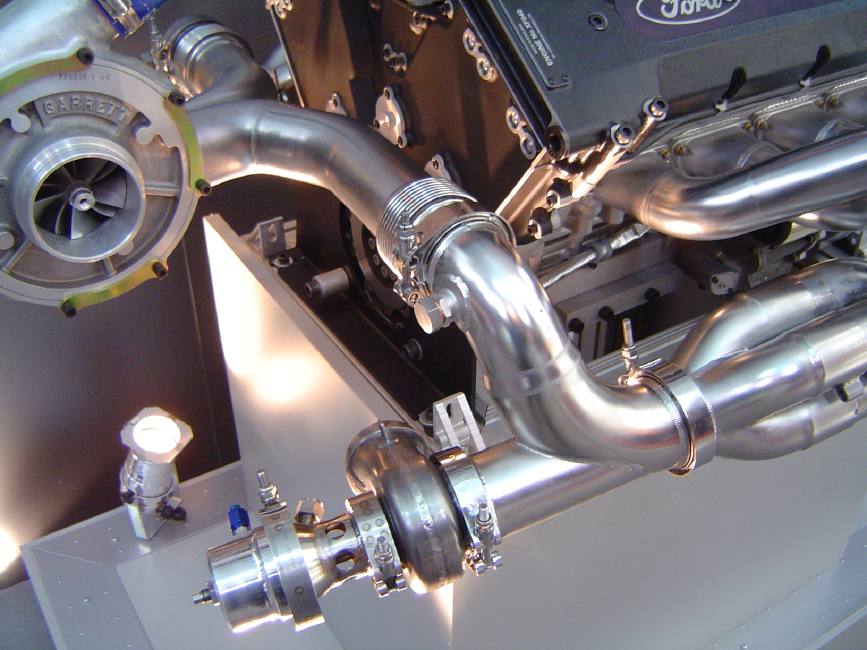

Mmm Cosworth XFE *wastegate* setup:

-

Lith - Toyspeed Member

- Posts: 3137

- Joined: Mon Dec 02, 2002 5:22 pm

- Location: Kapiti

Mr Revhead wrote:using a pop off valve on the intake has been used sucsessfully in motorsport for years. ie CART, F1, WSC etc

But in F1 if they overspun a turbo, they said "Bugger" and threw one of the spare ones one

1988 KE70 Wagon - Slowly rusting

1990 NA6 MX-5 - because reasons

2018 Ranger - Because workcar

1997 FD3S RX-7 Type R - all brap, all the time

OMG so shiny!

1990 NA6 MX-5 - because reasons

2018 Ranger - Because workcar

1997 FD3S RX-7 Type R - all brap, all the time

OMG so shiny!

Quint wrote:Not just cock, large cock.

-

Dell'Orto - ** Moderator **

- Posts: 17494

- Joined: Tue Jul 08, 2003 5:07 am

- Location: Straight out the ghetto, Lower Hutt

hehe yeah but u cant do that mid race

the big thing you have to remember with the nizpro set up.... is they have it working

i cant see any issues with it. in the right application

the big thing you have to remember with the nizpro set up.... is they have it working

i cant see any issues with it. in the right application

-

Mr Revhead - SECURITY!

- Posts: 24635

- Joined: Tue Jan 20, 2004 4:06 pm

- Location: Nelson

Mr Revhead wrote:hehe yeah but u cant do that mid race

the big thing you have to remember with the nizpro set up.... is they have it working

i cant see any issues with it. in the right application

Also actual full boost was controlled by having a turbo that was too small and would not flow enough at high rpm,

not like this where the turbo's are more than capable of massive flow.

- matt dunn

- Toyspeed Member

- Posts: 7109

- Joined: Fri Sep 12, 2003 1:01 am

- Location: Timaru

63 posts

• Page 3 of 4 • 1, 2, 3, 4

Return to General Car Discussion

Who is online

Users browsing this forum: Bing [Bot], Truenotch and 23 guests