How do they bend the pipes into those magnificent shapes? It's something I've always wondered.

Obviously if you 'crush bend' a pipe, it deforms the pipe out of round, which isnt ideal.

I think I recall someone saying that they fill the pipes with sand, so they dont 'crush' so much.

Do they heat the pipes perhaps?

For example 4-2-1 extractors, how do they make those great looking 4-2 sections using only one section of pipe for each runner? rather than welding individual sections of (presumably mandrel) bend in, like I see on some custom turbo manifolds.

I wouldnt mind having a go at making an exhaust manifold some time, using some formulas etc to get the pipe lengths correct, but I have no idea how it's done!

Even if it's just for the sake of doing it, I can see my first attempt not turning out quite right, haha.

I've got access to welding equipment, but no idea on what else is required.

Any help appreciated!

How are tubular exhaust manifolds made?

Moderator: The Mod Squad

13 posts

• Page 1 of 1

just buy off burns stainless

1988 Toyota Levin GTZ 410kw atw @26psi

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

-

Bazda - Toyspeed Sponsor

- Posts: 5713

- Joined: Sat Jun 01, 2002 10:32 pm

- Location: Auckland

- vvega

You'll find even the Bruns Stainless ones are welded, well the collectors anyway. They aren't all the difficult to make once you've done a few & know the angles etc you want.

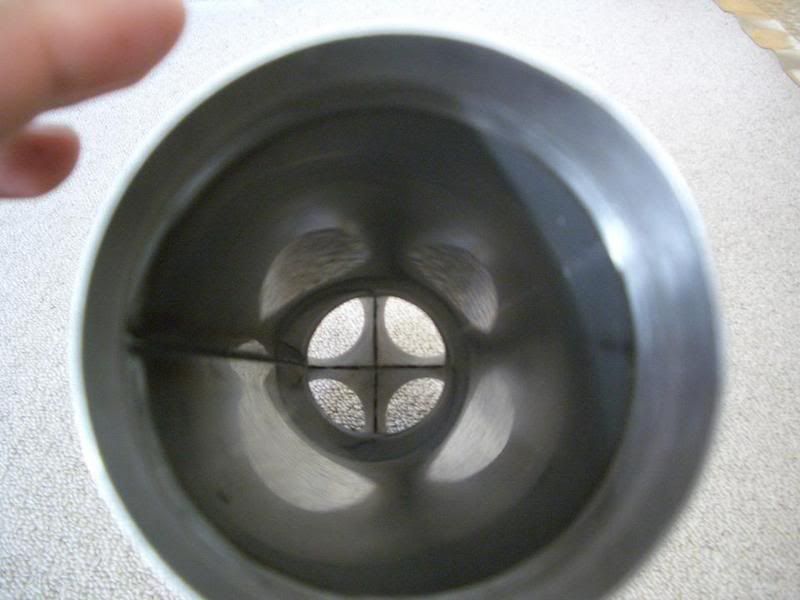

As for getting all those nicely curved pipes without any crushing in the bends & all the same length. Well yes you can CNC mandrel Bend them, or just mandrel bend to a template. Else you do it the poor man's way that we've been doing for years & buy boxes & boxes of mandrel bent donuts, 180's etc in the tube size & wall thickness you want & then tig weld them together to get what you want, various tips & tricks to getting them all the same length etc. Only thing is it takes a lot of time to do it properly, especially if you've got to fabricate oval sections & mufflers etc like we've just done to get what we wanted & also to keep the exhaust as close to the undersie of the car we can to try & reduce some more drag(any gain is worth having in a control class)

As for Sand bending, haven't do it in a while, though i have considered doing it for a scooter expansion chamber/exhuast I'm doing slowly at the moment. Basically you need to plug one end, pack it with sand really tighly & then plug the other end so the sand has no wear to go. Yes you will need to heat it & then you simply bend it by hand(probably need another bit of pipe on it to get leverage), heat the next section & away you go until you get what you want. My old man has a set here that he did which is actually older than me & we made by sand bending as mandrel bending back in the days was either mega $$$, not readily available here or hadn't been thought of yet. They still look like new, have no marks or crushed sections on them, however when pressed I was told never again as Mandrel bends & welding sections together is heaps easier & faster.

If you were doing heaps there are hydro-forming & various other methods available but cost would be prohibitive for a one off or small batch. Some of the 2-stroke expansion chambers are hydroformed & they've got some pretty intricate bends & section changes in them, I think basically it'd come done to getting someone to manufacture you moulds/dies etc.

As for getting all those nicely curved pipes without any crushing in the bends & all the same length. Well yes you can CNC mandrel Bend them, or just mandrel bend to a template. Else you do it the poor man's way that we've been doing for years & buy boxes & boxes of mandrel bent donuts, 180's etc in the tube size & wall thickness you want & then tig weld them together to get what you want, various tips & tricks to getting them all the same length etc. Only thing is it takes a lot of time to do it properly, especially if you've got to fabricate oval sections & mufflers etc like we've just done to get what we wanted & also to keep the exhaust as close to the undersie of the car we can to try & reduce some more drag(any gain is worth having in a control class)

As for Sand bending, haven't do it in a while, though i have considered doing it for a scooter expansion chamber/exhuast I'm doing slowly at the moment. Basically you need to plug one end, pack it with sand really tighly & then plug the other end so the sand has no wear to go. Yes you will need to heat it & then you simply bend it by hand(probably need another bit of pipe on it to get leverage), heat the next section & away you go until you get what you want. My old man has a set here that he did which is actually older than me & we made by sand bending as mandrel bending back in the days was either mega $$$, not readily available here or hadn't been thought of yet. They still look like new, have no marks or crushed sections on them, however when pressed I was told never again as Mandrel bends & welding sections together is heaps easier & faster.

If you were doing heaps there are hydro-forming & various other methods available but cost would be prohibitive for a one off or small batch. Some of the 2-stroke expansion chambers are hydroformed & they've got some pretty intricate bends & section changes in them, I think basically it'd come done to getting someone to manufacture you moulds/dies etc.

- atmosports

- Toyspeed Member

- Posts: 569

- Joined: Fri Jul 04, 2003 7:52 pm

- Location: Auckland,New Zealand

t

well duh! I dont think people make a wooden square block, heat the tube red hot and wack the wood in. And making one out of steel and being tapered would take alot of work, plus some ports arnt excatly square and different engines are different sizes too.

- catchafox

- Toyspeed Member

- Posts: 65

- Joined: Fri Aug 11, 2006 9:37 pm

- Location: North Shore Akl

1988 Toyota Levin GTZ 410kw atw @26psi

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

-

Bazda - Toyspeed Sponsor

- Posts: 5713

- Joined: Sat Jun 01, 2002 10:32 pm

- Location: Auckland

Re: pipe

catchafox wrote:where in akl is the best place to get bends and donuts for m/steel s/s and alloy?

tube bending ltd

1988 Toyota Levin GTZ 410kw atw @26psi

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

-

Bazda - Toyspeed Sponsor

- Posts: 5713

- Joined: Sat Jun 01, 2002 10:32 pm

- Location: Auckland

13 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 6 guests