Water pump

Moderator: The Mod Squad

39 posts

• Page 2 of 2 • 1, 2

Jabsco raw water pump, generally used in marine colling systems,

Try the likes of lusty and blundall, burnsco etc

Heaps of variety,

Jabsco is a brand, and usually at the expensive end, there are other cheaper brands also but no brand names tha i can think of

Try the likes of lusty and blundall, burnsco etc

Heaps of variety,

Jabsco is a brand, and usually at the expensive end, there are other cheaper brands also but no brand names tha i can think of

-

evil_si - Toyspeed Member

- Posts: 2353

- Joined: Sat Nov 01, 2003 6:19 pm

- Location: TAURANGA, Pyes Pa

-

Mr Revhead - SECURITY!

- Posts: 24635

- Joined: Tue Jan 20, 2004 4:06 pm

- Location: Nelson

Grrrrrrr! wrote:sergei wrote:

3) Brand new ST205 pump is a tad over $100, and flows well enough to satisfy your needs (or any other needs).

So what flow rate exactly does a st205 pump provide at 5psi,8psi and 10psi, i'd love to know, because so far i haven't been able to find any actual data on what that pump flows. Then if you could just tell me exactly what my needs are it'll save me a bit of time and a bunch of heat transfer calcs.. kthxbye.

You haven't told us anything about how much heat you want to dissipate.

One would assume you definitely do not make 1000kW, and most likely your engine output is below 500kW. Hence my assumption that ST205 water pump will be sufficient. I do not have figures for ST205 water pump. I do have figures for Legacy AWIC system.

Basically the legacy Intercooler has capacity of about 4kW heat dissipation, while the radiator is at about 5kW, the pump which runs this system is rated at 15L/min, and is not running full time.

The ST205 intercooler has bigger core, the radiator is more than twice larger, and pump is definitely larger. Actually compared to Subaru (or ST165, as they are almost identical) the pump is much larger, the impeller is massive. The outlets are larger as well.

I would put the ST205 intercooler at about 10+kW of dissipation capacity. Pump is definitely not a problem in this system.

As for pressure, you would be struggling to find any centrifugal water pumps that will work well above 0.3bars of restriction.

Here is some real life data:

My setup was ST205 intercooler, Legacy I/C radiator and 15L/h pump (legacy/ST165). The intake temperatures were stable at 195kW at the wheels, which means the legacy 5kW is sufficient up to 200kW at the wheels (of course that depending how efficient is your turbo). This also suggests that 15L/h pump was also sufficient for the task.

Of course I will be upgrading legacy I/C radiator and pump to ST205 units, because the car will be seeing some track duties and the conditions (the air flow through radiator) will not be the same as on the dyno.

-

sergei - Mad Russian

- Posts: 8406

- Joined: Wed May 15, 2002 12:06 pm

- Location: North Shore

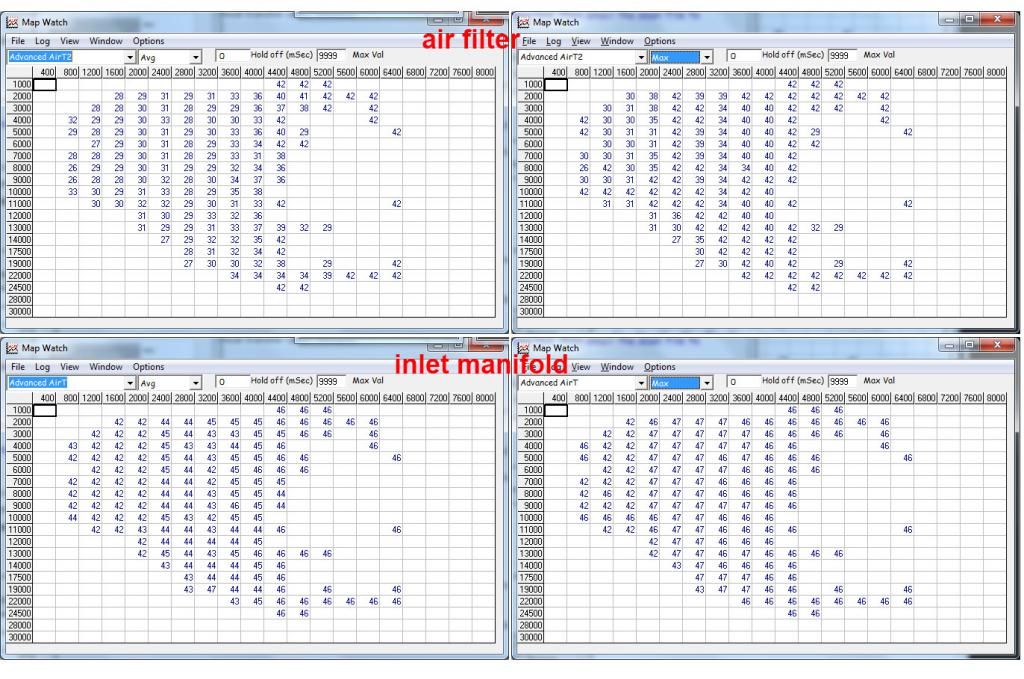

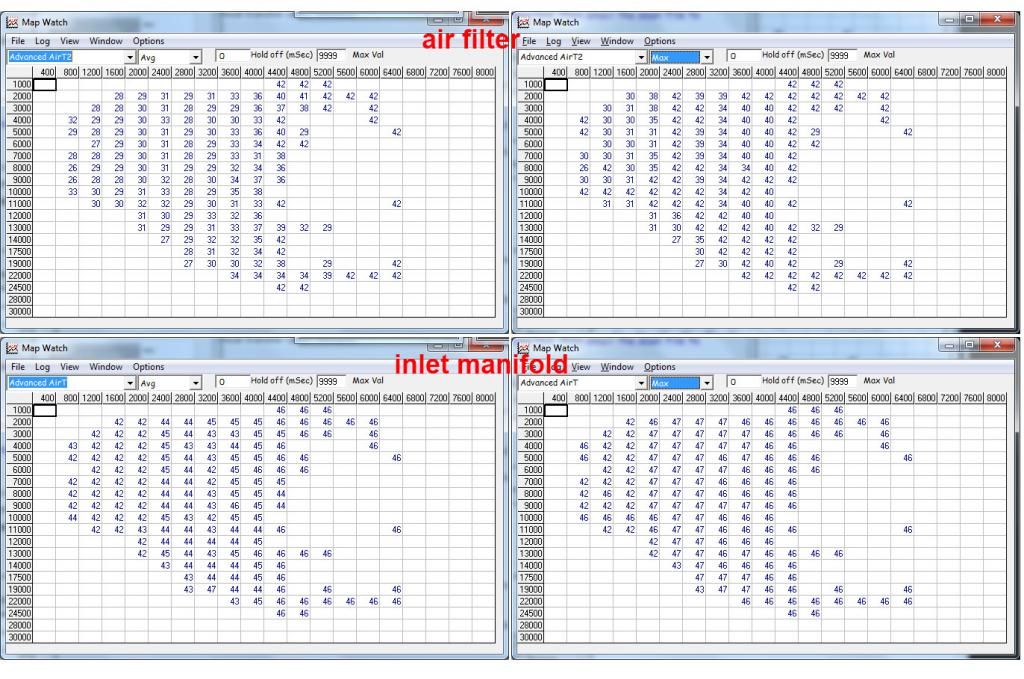

here is some real real life data of me giving it a squirt the other day

ambient + 12 deg consistent, 22000 on the load axis is 1.1bar of boost, 24500 is 1.3bar, so power is roughly 180-190kw on 4 wheels

ambient + 12 deg consistent, 22000 on the load axis is 1.1bar of boost, 24500 is 1.3bar, so power is roughly 180-190kw on 4 wheels

Last edited by gt4dude on Mon Jan 07, 2013 10:31 am, edited 2 times in total.

セリカGT-FOUR ST205 中期型 (Chuuki)

GT2860RS ・ JE 86.5φ PISTON ・ FX400 CLUTCH ・ APEX P-FC

200AWKW / 370NM

GT2860RS ・ JE 86.5φ PISTON ・ FX400 CLUTCH ・ APEX P-FC

200AWKW / 370NM

-

gt4dude - Toyspeed Member

- Posts: 723

- Joined: Wed Apr 07, 2010 10:56 am

- Location: Auckland

On a hot day, there is roughly 30kW of heat to lose to get intake temps to where i want them (about 30* above ambient) judging from ballpark figures I punched into the borg warner turbo selector website.

Piping may have to get larger to keep the restriction down to 5psi max, but high flow is the only option to keep the size of the intercooler core and heat exchanger reasonable.

Piping may have to get larger to keep the restriction down to 5psi max, but high flow is the only option to keep the size of the intercooler core and heat exchanger reasonable.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Grrrrrrr! wrote:On a hot day, there is roughly 30kW of heat to lose to get intake temps to where i want them (about 30* above ambient) judging from ballpark figures I punched into the borg warner turbo selector website.

Piping may have to get larger to keep the restriction down to 5psi max, but high flow is the only option to keep the size of the intercooler core and heat exchanger reasonable.

I am interested in those calculations.... 30kW is a lot of heat.

-

sergei - Mad Russian

- Posts: 8406

- Joined: Wed May 15, 2002 12:06 pm

- Location: North Shore

turbo outlet temp 325F = 162*C (from matchbot)

Mass flow = 0.302kg/s (from matchbot)

desired throttle body temp 60*C

DeltaT = 102*C

specific heat capacity of air ~1 kJ/K.kg

0.302 * 102 * 1 = 30.8kW.

and thats only at 400 hp power levels.

Mass flow = 0.302kg/s (from matchbot)

desired throttle body temp 60*C

DeltaT = 102*C

specific heat capacity of air ~1 kJ/K.kg

0.302 * 102 * 1 = 30.8kW.

and thats only at 400 hp power levels.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Grrrrrrr! wrote:turbo outlet temp 325F = 162*C (from matchbot)

Mass flow = 0.302kg/s (from matchbot)

desired throttle body temp 60*C

DeltaT = 102*C

specific heat capacity of air ~1 kJ/K.kg

0.302 * 102 * 1 = 30.8kW.

and thats only at 400 hp power levels.

Working backwards (from 0.302kg/s) I assume you are going to run something like 1.5-1.7Bar on a 2.0L? That would explain 160+ 'C and >30kW dissipation needed.

-

sergei - Mad Russian

- Posts: 8406

- Joined: Wed May 15, 2002 12:06 pm

- Location: North Shore

0.3kg/s = ~400ish hp. Smallish turbo, and high pressure ratios for early spool.

Evil-si: thanks for the suggestions, they look worthy of further investigation, but pretty $$$ from the one price i checked.

Evil-si: thanks for the suggestions, they look worthy of further investigation, but pretty $$$ from the one price i checked.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

sounds alot like your over-thinking / deliberately making things hard when there are multiple simple issues in the page above.

- d1 mule

- Toyspeed Member

- Posts: 1790

- Joined: Sun Dec 18, 2005 9:32 pm

- Location: perth, WA

Yes, there are multiple issues, hence why i'm doing some research and looking at options. unfortunately a big FMIC isn't an option, or there would be no drama and i wouldn't be faffing around looking at w2a. Got anything constructive to contribute?

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Faster water flow through the radiator core will not always be better, there needs to be time for the heat transfer to occur.

Maybe something to consider.. (not sure on the exact figures so happy to be proven wrong)

Maybe something to consider.. (not sure on the exact figures so happy to be proven wrong)

- nz_climber

- Toyspeed Member

- Posts: 322

- Joined: Sat Dec 20, 2003 10:29 pm

- Location: Bulls

nz_climber wrote:Faster water flow through the radiator core will not always be better, there needs to be time for the heat transfer to occur.

Maybe something to consider.. (not sure on the exact figures so happy to be proven wrong)

Thats just another internet myth.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

FWIW we run a single small electric water pump on the W2A intercooler on the MRS,

and another electric one for main radiator cooling too.

Not very good pic's but here are some from the build thread showing the pumps we used.

http://i277.photobucket.com/albums/kk58 ... pic137.jpg

shows the IC pump,

http://i277.photobucket.com/albums/kk58 ... pic860.jpg

shows the pump for the radiator, as the engine had no water pump itself anymore.

and another electric one for main radiator cooling too.

Not very good pic's but here are some from the build thread showing the pumps we used.

http://i277.photobucket.com/albums/kk58 ... pic137.jpg

shows the IC pump,

http://i277.photobucket.com/albums/kk58 ... pic860.jpg

shows the pump for the radiator, as the engine had no water pump itself anymore.

- matt dunn

- Toyspeed Member

- Posts: 7109

- Joined: Fri Sep 12, 2003 1:01 am

- Location: Timaru

Grrrrrrr! wrote:nz_climber wrote:Faster water flow through the radiator core will not always be better, there needs to be time for the heat transfer to occur.

Maybe something to consider.. (not sure on the exact figures so happy to be proven wrong)

Thats just another internet myth.

Not quite a myth. In every heat transfer there is a time factor. How fast the heat is transferred is dictated by temperature difference. It will cool faster if it is hotter, it will heat faster if it is colder.

http://www.physicsclassroom.com/class/thermalP/u18l1f.cfm

So theoretically having too much flow will increase average temperature.

-

sergei - Mad Russian

- Posts: 8406

- Joined: Wed May 15, 2002 12:06 pm

- Location: North Shore

Correct, the rate of heat tranfers is dictated by the temperature difference which is why more mass flow wins every time. More mass flow means you are pushing the water that has already cooled away from the face of the heat exchanger and replacing it with warmer water, therefore it is more efficient.

That graph is irrelevant, thats for heat transfer between two masses in a closed system. Not relevant to an open system with net energy changes.

Go to this website and play with the calculator. Setup some numbers, then double one of the flow rates... result is more heat transfer, everytime.

That graph is irrelevant, thats for heat transfer between two masses in a closed system. Not relevant to an open system with net energy changes.

Go to this website and play with the calculator. Setup some numbers, then double one of the flow rates... result is more heat transfer, everytime.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Grrrrrrr! wrote:Correct, the rate of heat tranfers is dictated by the temperature difference which is why more mass flow wins every time. More mass flow means you are pushing the water that has already cooled away from the face of the heat exchanger and replacing it with warmer water, therefore it is more efficient.

That graph is irrelevant, thats for heat transfer between two masses in a closed system. Not relevant to an open system with net energy changes.

Go to this website and play with the calculator. Setup some numbers, then double one of the flow rates... result is more heat transfer, everytime.

That calculator is irrelevant as all it probably does is fudges the data into the preset calculations. Without seeing the source of the calculator (and formulae they used to calculate). I have no trust in the programmers

-

sergei - Mad Russian

- Posts: 8406

- Joined: Wed May 15, 2002 12:06 pm

- Location: North Shore

matt dunn wrote:

http://i277.photobucket.com/albums/kk58 ... pic860.jpg

shows the pump for the radiator, as the engine had no water pump itself anymore.

2nd pic / engine pump looks like a davies craig. Have you had any issues with it ?

Reason i ask is i'm using one for the W2A and it regularly burns the seal out, letting water into the motor / out of the system and then next time i use it the bearing have seized in the motor.

What problems did the Formula SAE car have GRRRR

- Guss

- Toyspeed Member

- Posts: 123

- Joined: Wed Jan 26, 2005 7:50 pm

- Location: Auckland

39 posts

• Page 2 of 2 • 1, 2

Who is online

Users browsing this forum: No registered users and 10 guests