I was thinking this week about VVT and boost and how the two relate to each other. For this example I was using the 4age 20V.

It is my understanding that with stock cams, VVT operates to increase overlap by 30 degrees by twisting the camshaft via the intake cam pulley. What this means is that the cam is advanced by 30 degrees so that the intake opens early but also closes early. The theory is that by increasing the overlap the intake is exposed to the negative pressures generated by the exhaust system for longer thus passing that negative pressure into the intake. This negative pressure initiates air movement into the cylinder and across the piston even though the piston is still rising. This clears out the combustion chamber of any residual exhaust gas with cool, oxygen rich air. The negative pressure can be increased by changing the length and size of your extractors and exhaust and so increasing torque further.

Under low load, VVT is off giving a factory overlap of zero. Its not hard to see why there is an increase in torque when VVT is activated. However, there is a distinct disadvantage in higher RPM and that's the intake cam closing 30 degrees earlier when VVT is on. While closing the intake valve earlier in low RPM increases torque by having the cylinder trap the fresh charge more efficiently, the downside is as RPM rises it robs the engine of the ramming effect of a later intake valve closing. Factory setting is to turn VVT off at 7000RPM as that is when Toyota have found that is where VVT is no longer useful for this reason.

Hopefully I explained that well enough to be understood. It is also the basis for the next presumption.

When the 4age 20V starts to be modified with an aftermarket ECU, most tuners operate VVT via the TPS, setting it to switch on anywhere from 20-35% in N/A form. However, I'm wondering if doing the same for a turbo application isn't the best way to go.

To my understanding, turbos work with pressure. Good turbo setups work at a 1:1 ratio where intake manifold pressure is the same as exhaust manifold pressure. So, turning VVT on to increase overlap when the pressure in the exhaust system is positive and rising, doesn't make sense. It would be better to have VVT deactivated with a pressure switch set at say 2-4psi. Under this VVT should be active as the exhaust has either a negative pressure or little positive pressure making use of the benefits of overlap so increasing low RPM torque. When intake pressure increases VVT should then be switched off so that overlap reduces. Reducing the overlap stops exhaust gas pressure diluting the incoming boost and with the later valve closing takes advantage of the boost applied.

Its what I was thinking and the theory behind it anyway and thought it would start some decent discussion with the gear heads on here.

Just to highlight, the theory I've set out above, it would increase torque by operating VVT the opposite way to N/A for a turbo setup. Maybe the gifted few who do have a turbo setup have this already, or someone with tuning experience can confirm that this works or it doesn't.

VVT and Boost (Indepth Theory Questions)

Moderator: The Mod Squad

9 posts

• Page 1 of 1

VVT and Boost (Indepth Theory Questions)

The Flannel, formally known as Affroman

- Flannelman

- formerly known as Affroman

- Posts: 461

- Joined: Mon Jul 19, 2004 9:43 pm

- Location: Old Plymouth

I've had some thoughts about this also...

With a few dyno sessions you could play with the cam timing (base and vvt) to get an optimum (or least worst) setting.

One option is to put a pressure (MAP) sensor on the exhaust manifold (before the turbo). Then have the computer reduce overlap when exhaust pressure is higher than intake pressure.

I think Matt Dunn accidentally raced for a couple of seasons with exhaust cam timing out by a tooth - still had loads of power!

You'd be very lucky to get 1:1 intake:exhaust pressure ratio in most turbo applications. Turbo F1 cars from the 80's had 1:1 ratios due to huge development budgets

Probably find a 1:2 ratio for many turbo setups.

With a few dyno sessions you could play with the cam timing (base and vvt) to get an optimum (or least worst) setting.

One option is to put a pressure (MAP) sensor on the exhaust manifold (before the turbo). Then have the computer reduce overlap when exhaust pressure is higher than intake pressure.

I think Matt Dunn accidentally raced for a couple of seasons with exhaust cam timing out by a tooth - still had loads of power!

You'd be very lucky to get 1:1 intake:exhaust pressure ratio in most turbo applications. Turbo F1 cars from the 80's had 1:1 ratios due to huge development budgets

Probably find a 1:2 ratio for many turbo setups.

I used to think that the orange and green tictacs gave you special powers. The orange ones would make you stronger and the green ones would make you faster. So i used to eat some green ones and run around my lounge as fast as i could, then eat the orange ones and try to pick up the sofa. I wish it were true!

-

KinLoud - ** Moderator **

- Posts: 2893

- Joined: Thu May 16, 2002 7:39 pm

- Location: Auckland

not to sure about "dumb" vvt but VVTi advances the cam from 1000rpm and slowly retards it back to normal as rpm increases. The earlier the inlet valve closes the lower down the rpm range its make peak torque.

so at idle its as per normal, at 1000rpm it might be 20 degrees advanced, and at 2000-3000rpm its close to max advance (depending on load) of around 40 degrees and then slowly retarded back to zero by around 5500rpm. Inlet valve closing timing has the biggest bearing on when peak torque is made.

so at idle its as per normal, at 1000rpm it might be 20 degrees advanced, and at 2000-3000rpm its close to max advance (depending on load) of around 40 degrees and then slowly retarded back to zero by around 5500rpm. Inlet valve closing timing has the biggest bearing on when peak torque is made.

Online Car Forums - Where Hui seems to take preference over Do-ey

HDJ81- 112AWKW @ 10psi), FC3S (Tarmac Spec 335rwhp@11psi), 3SGTE stroker - replacement body found.

Motorsport Bay of Plenty - http://www.mbop.org.nz

HDJ81- 112AWKW @ 10psi), FC3S (Tarmac Spec 335rwhp@11psi), 3SGTE stroker - replacement body found.

Motorsport Bay of Plenty - http://www.mbop.org.nz

- strx7

- Toyspeed Member

- Posts: 3707

- Joined: Mon May 24, 2004 12:06 am

- Location: Tauranga

So I've got a turbo 20v 4age with the VVT enabled.

It was tuned by speedtech and they set it up to turn on (30 degree advance) the cam at 2000rpm and turn off at 6000rpm, it's only checking for rpm not throttle position or anything else.

Right now the VVT on my car isn't working right - I think I put a silvertop intake pulley on by accident, but I can now tell when the VVT turns on and off.

The difference the VVT makes with the turbo is that above 6000rpm the engine is much happier to rev, feels like a 2 stroke in its powerband, with the VVT not working right there's still a lot of power, but it feels like it's choking a bit.

So the VVT turning off and on does make a difference when turbocharged. If it would work better based on boost level or throttle position I don't know, I guessing speedtech have a pretty good idea what works and what doesn't, so maybe RPM based switching is the way to go.

It was tuned by speedtech and they set it up to turn on (30 degree advance) the cam at 2000rpm and turn off at 6000rpm, it's only checking for rpm not throttle position or anything else.

Right now the VVT on my car isn't working right - I think I put a silvertop intake pulley on by accident, but I can now tell when the VVT turns on and off.

The difference the VVT makes with the turbo is that above 6000rpm the engine is much happier to rev, feels like a 2 stroke in its powerband, with the VVT not working right there's still a lot of power, but it feels like it's choking a bit.

So the VVT turning off and on does make a difference when turbocharged. If it would work better based on boost level or throttle position I don't know, I guessing speedtech have a pretty good idea what works and what doesn't, so maybe RPM based switching is the way to go.

- ATAl

- Toyspeed Member

- Posts: 486

- Joined: Tue Nov 23, 2004 8:16 pm

- Location: Wellington

ATAl wrote:So I've got a turbo 20v 4age with the VVT enabled.

It was tuned by speedtech and they set it up to turn on (30 degree advance) the cam at 2000rpm and turn off at 6000rpm, it's only checking for rpm not throttle position or anything else.

My turbo 20V was about the same

VVT on just after idle and around 6200 it turned off.

I now run fixed adjustable cam wheels with aftermarket cams,

but the std cams with VVT were better,

slightly less power with std cams and VVT but wider power range.

- matt dunn

- Toyspeed Member

- Posts: 7109

- Joined: Fri Sep 12, 2003 1:01 am

- Location: Timaru

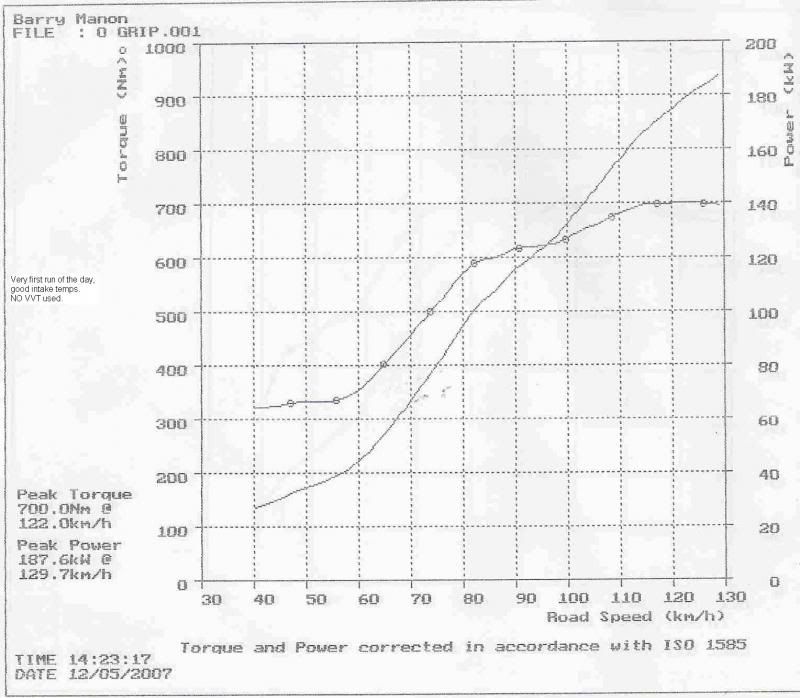

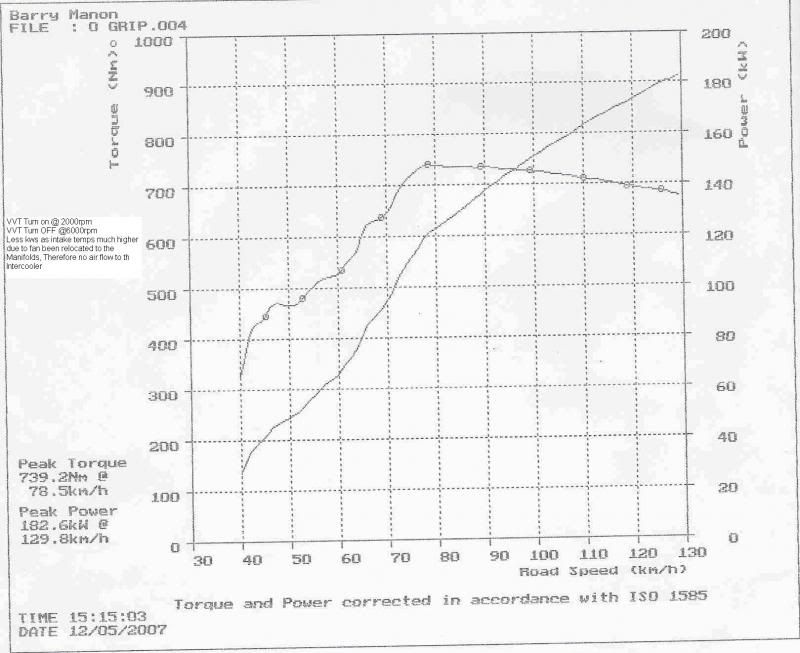

I tested this back in 2007.

We tested various points to turb on/off VVT.

2000rpm on and 6000rpm off was about right.

Here are the Dyno plots

All done on 7-8psi of boost as this was my run in tune.

You can see the massive difference with VVT on and off.

For instance @78kph VVT off 550Nm/90kw

VVT on 740Nm/120kw

Thats a 30kw gain, im guessing that was around 5000rpm.

The final power run when we used VVT was slightly down up high due to intake temps as the dyno fan was packing a sad.

VVT off

VVT on

We tested various points to turb on/off VVT.

2000rpm on and 6000rpm off was about right.

Here are the Dyno plots

All done on 7-8psi of boost as this was my run in tune.

You can see the massive difference with VVT on and off.

For instance @78kph VVT off 550Nm/90kw

VVT on 740Nm/120kw

Thats a 30kw gain, im guessing that was around 5000rpm.

The final power run when we used VVT was slightly down up high due to intake temps as the dyno fan was packing a sad.

VVT off

VVT on

1988 Toyota Levin GTZ 410kw atw @26psi

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

-

Bazda - Toyspeed Sponsor

- Posts: 5713

- Joined: Sat Jun 01, 2002 10:32 pm

- Location: Auckland

Re: VVT and Boost (Indepth Theory Questions)

Silly question but would vvt coming on earlier help the silvertop make more power with a low boost (6psi ) application?

Would this help the off boost performance as the engine has a 11:1 comp ratio.

Would this help the off boost performance as the engine has a 11:1 comp ratio.

- 1984FXGT

- Toyspeed Member

- Posts: 60

- Joined: Mon Oct 21, 2013 1:51 pm

Re: VVT and Boost (Indepth Theory Questions)

1984FXGT wrote:Silly question but would vvt coming on earlier help the silvertop make more power with a low boost (6psi ) application?

Would this help the off boost performance as the engine has a 11:1 comp ratio.

Silvertops are 10.5:1 Blacktops are 11:1

Why dream it when you can live it

-

Shrike - Toyspeed Member

- Posts: 731

- Joined: Fri Jul 01, 2011 3:05 pm

- Location: Melbourne

Re: VVT and Boost (Indepth Theory Questions)

7afe or trd headgasket makes silvertop 11:1

- 1984FXGT

- Toyspeed Member

- Posts: 60

- Joined: Mon Oct 21, 2013 1:51 pm

9 posts

• Page 1 of 1

Who is online

Users browsing this forum: Bing [Bot] and 6 guests