torquing down 16v head

Moderator: The Mod Squad

23 posts

• Page 1 of 2 • 1, 2

torquing down 16v head

Hey guys ive done a bit of searching and haven't found my answer

Im replacing my ae101 4agze head gasket with a cometic mls gasket and new head bolts

What I want to know is what method I should use to torque down the head?

Some say go to 22# +90 +90 then others say 3 pssses up to 44#-48#

Id imagine that a mls gasket wouldnt compress as much as a oem gasket so the 22# +90 +90 would be a bit overkill

Can anyone enlighten me?

Im replacing my ae101 4agze head gasket with a cometic mls gasket and new head bolts

What I want to know is what method I should use to torque down the head?

Some say go to 22# +90 +90 then others say 3 pssses up to 44#-48#

Id imagine that a mls gasket wouldnt compress as much as a oem gasket so the 22# +90 +90 would be a bit overkill

Can anyone enlighten me?

82 4DR KP62 4AGTE MADNESS

98 RS200 ALTEZZA

98 RS200 ALTEZZA

-

sk1dlet - Toyspeed Member

- Posts: 259

- Joined: Fri Jan 07, 2005 9:26 pm

- Location: Te Aroha

Re: torquing down 16v head

22ft-lbs +90+90 is correct if using oem bolts. If using ARPs etc use what the head bolt manufacturer recommends.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Re: torquing down 16v head

Does that work for a metal head gasket as well

82 4DR KP62 4AGTE MADNESS

98 RS200 ALTEZZA

98 RS200 ALTEZZA

-

sk1dlet - Toyspeed Member

- Posts: 259

- Joined: Fri Jan 07, 2005 9:26 pm

- Location: Te Aroha

Re: torquing down 16v head

when torquing down at 22# do you keep doing passes in sequence till all bolts hold at 22# then do +90 +90?

82 4DR KP62 4AGTE MADNESS

98 RS200 ALTEZZA

98 RS200 ALTEZZA

-

sk1dlet - Toyspeed Member

- Posts: 259

- Joined: Fri Jan 07, 2005 9:26 pm

- Location: Te Aroha

Re: torquing down 16v head

There is a specific sequence you should use. See here for just the cylinder head assembly info - https://goo.gl/o5U58p

Here is a link to the complete workshop manual for 16v motors http://files.aeu86.org/manuals/4A-GEManual.pdf Page 230 (EM-117 - EM-124)

If you do it wrong, the head gasket won't last long.

Here is a link to the complete workshop manual for 16v motors http://files.aeu86.org/manuals/4A-GEManual.pdf Page 230 (EM-117 - EM-124)

If you do it wrong, the head gasket won't last long.

-

Pelo - ** Moderator **

- Posts: 631

- Joined: Wed Feb 25, 2004 9:01 pm

- Location: Auckland

Re: torquing down 16v head

Have a read here...

http://club4ag.com/forums/viewtopic.php?f=13&t=8685

I don't know if the GZE has TTY bolts, but if it does the TTY method

of torquing the bolts applies only if you are using the OEM gasket. Once

you change to a MLS gasket (which will compress at a different rate)

you need to torque to a specific value no matter what bolts you use.

If you want, you could try the TTY method, but set your torque wrench

to say 50 ft-lb and see how far you get into the 90 + 90 sequence before

the wrench hits 50 ft-lb.

Cheers... jondee86

http://club4ag.com/forums/viewtopic.php?f=13&t=8685

I don't know if the GZE has TTY bolts, but if it does the TTY method

of torquing the bolts applies only if you are using the OEM gasket. Once

you change to a MLS gasket (which will compress at a different rate)

you need to torque to a specific value no matter what bolts you use.

If you want, you could try the TTY method, but set your torque wrench

to say 50 ft-lb and see how far you get into the 90 + 90 sequence before

the wrench hits 50 ft-lb.

Cheers... jondee86

1984 AE86 Corolla GT Liftback, NZ new... now with GZE

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

-

jondee86 - Toyspeed Member

- Posts: 903

- Joined: Mon Aug 18, 2003 11:08 pm

- Location: Wellington

Re: torquing down 16v head

No, its the bolt that matters, not the gasket.

From a manufacturer of MLS headgaskets..

From a manufacturer of MLS headgaskets..

.Cometic wrote:What head bolt/stud torque do you recommend when using an MLS gasket?

When using MLS head gaskets always refer to the manufacturer of the fastener to determine accurate torque values. Appropriate torque is critical when installing new gaskets of any kind.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Re: torquing down 16v head

OK... perhaps I did not explain that very well

The interwebs and even the various factory and industry manuals are

far from clear on how the head should be torqued once there is any

deviation from the original factory combination of gasket and bolt type.

Here are five different possible 4AGE head clamping combinations...

1. Composite gasket with TTY bolts (factory combo)

The gasket is "soft" and compressible, so preload plus 90 plus 90.

2. Composite gasket with standard bolts (factory combo)

Torque to factory specified torque.

3. MLS gasket with TTY bolts (factory combo)

The gasket is "hard" and compressible so torque-angle method.

4. MLS gasket with standard bolts

Torque to gasket suppliers specifications.

5. Any gasket with ARP bolts/studs

Torque to ARP specified torque.

The problem area is when the factory composite gasket is replaced with

a MLS gasket. On a factory composite + TTY combo the preload torque

and angle will have been calculated by the factory to obtain the correct

amount of stretch in the bolts when using new OEM TTY bolts and a new

OEM composite gasket.

MLS gaskets will compress less than a composite gasket, and once the

"ridges" in the gasket are compressed flat, the rate of increase in clamping

force per degree of rotation will be MUCH higher than a composite gasket.

Replacing a "soft" OEM composite gasket with a "hard" MLS gasket and using

the same TTY method (90 plus 90) for torquing the head can result in major

problems due to over-torquing. The situation becomes even more dubious

when TTY bolts are reused or the TTY method is used with standard bolts.

Cheers... jondee86

The interwebs and even the various factory and industry manuals are

far from clear on how the head should be torqued once there is any

deviation from the original factory combination of gasket and bolt type.

Here are five different possible 4AGE head clamping combinations...

1. Composite gasket with TTY bolts (factory combo)

The gasket is "soft" and compressible, so preload plus 90 plus 90.

2. Composite gasket with standard bolts (factory combo)

Torque to factory specified torque.

3. MLS gasket with TTY bolts (factory combo)

The gasket is "hard" and compressible so torque-angle method.

4. MLS gasket with standard bolts

Torque to gasket suppliers specifications.

5. Any gasket with ARP bolts/studs

Torque to ARP specified torque.

The problem area is when the factory composite gasket is replaced with

a MLS gasket. On a factory composite + TTY combo the preload torque

and angle will have been calculated by the factory to obtain the correct

amount of stretch in the bolts when using new OEM TTY bolts and a new

OEM composite gasket.

MLS gaskets will compress less than a composite gasket, and once the

"ridges" in the gasket are compressed flat, the rate of increase in clamping

force per degree of rotation will be MUCH higher than a composite gasket.

Replacing a "soft" OEM composite gasket with a "hard" MLS gasket and using

the same TTY method (90 plus 90) for torquing the head can result in major

problems due to over-torquing. The situation becomes even more dubious

when TTY bolts are reused or the TTY method is used with standard bolts.

Cheers... jondee86

1984 AE86 Corolla GT Liftback, NZ new... now with GZE

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

-

jondee86 - Toyspeed Member

- Posts: 903

- Joined: Mon Aug 18, 2003 11:08 pm

- Location: Wellington

Re: torquing down 16v head

And yet the dodge tsb for changing from composite to mls headgaskets in 2.0l sohc and 2.4l engines says to use the same torque values as with composite gaskets. They changed it for the dohc engine, but probably becuase they were known to blow hg every 100kms anyway and would have no doubt had to change it for composite gaskets if they had not gone to mls.

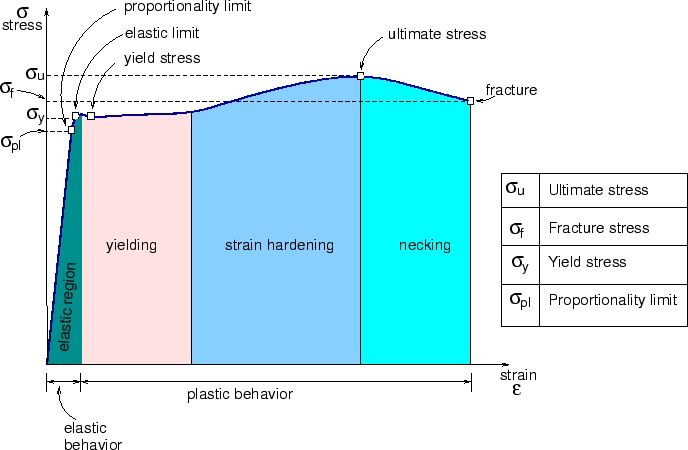

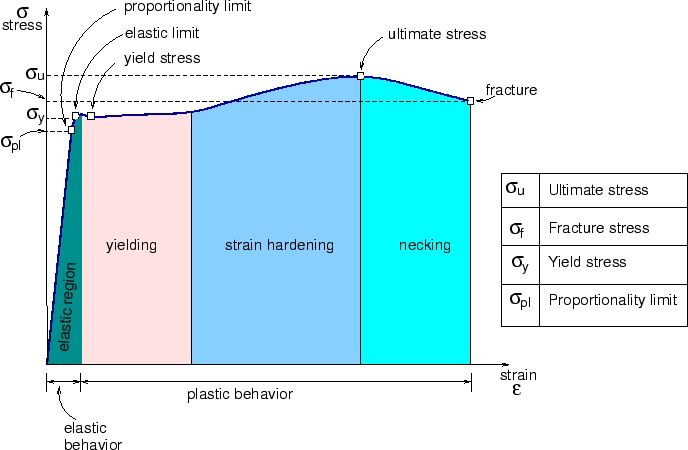

The whole point of tty is that there is far less variability of clamp forces due to taking it into the yield region. Look at an enginnering stress/strain chart for a steel bolt and it is obvious why.

If mls headgaskets required different torque values they would supply the torque values with the gaskets.. but they dont. They supply different torque values with aftermarket head bolts/studs because that is what determines the correct clamping force.

As for tty bolt vs std bolt.. for the 16v 4age they are the SAME bolt, toyota revised the torquing procedure as the engines went up in power output to acheive higher and more consistent clampling pressure.

Cometic says use std torque values, chysler says use std torque values, internet forums say all sort of BS.

On my phone or I'd check another example.. 3sgte. Gen 2 had composite gasket, gen 3 had mls as std. I bet they use the same bolts and torque values.

The whole point of tty is that there is far less variability of clamp forces due to taking it into the yield region. Look at an enginnering stress/strain chart for a steel bolt and it is obvious why.

If mls headgaskets required different torque values they would supply the torque values with the gaskets.. but they dont. They supply different torque values with aftermarket head bolts/studs because that is what determines the correct clamping force.

As for tty bolt vs std bolt.. for the 16v 4age they are the SAME bolt, toyota revised the torquing procedure as the engines went up in power output to acheive higher and more consistent clampling pressure.

Cometic says use std torque values, chysler says use std torque values, internet forums say all sort of BS.

On my phone or I'd check another example.. 3sgte. Gen 2 had composite gasket, gen 3 had mls as std. I bet they use the same bolts and torque values.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Re: torquing down 16v head

Grrrrrrr! wrote:And yet the dodge tsb for changing from composite to mls headgaskets

in 2.0l sohc and 2.4l engines says to use the same torque values as with

composite gaskets.

Does this mean they used the same specific torque, or the same torque-angle method ?

If mls headgaskets required different torque values they would supply the torque values

with the gaskets.. but they dont. They supply different torque values with aftermarket

head bolts/studs because that is what determines the correct clamping force.

Agreed.

As for tty bolt vs std bolt.. for the 16v 4age they are the SAME bolt, toyota revised

the torquing procedure as the engines went up in power output to acheive higher and

more consistent clampling pressure.

Now this ^^^^ explains a lot of the confusion (mine included). Toyota changed to the

torque-angle method but used standard bolts !!!!. And as most people associate the

torque-angle method with TTY bolts, the arguments began

Cheers... jondee86

1984 AE86 Corolla GT Liftback, NZ new... now with GZE

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

-

jondee86 - Toyspeed Member

- Posts: 903

- Joined: Mon Aug 18, 2003 11:08 pm

- Location: Wellington

Re: torquing down 16v head

Does this mean they used the same specific torque, or the same torque-angle method ?

No idea, they aren't in the tsb and I pray I never have to work on a dodge/chrysler. The new procedure for the dohc motor is torque-angle.

As for tty bolt vs std bolt.. for the 16v 4age they are the SAME bolt, toyota revised

the torquing procedure as the engines went up in power output to acheive higher and

more consistent clampling pressure.

Now this ^^^^ explains a lot of the confusion (mine included). Toyota changed to the

torque-angle method but used standard bolts !!!!. And as most people associate the

torque-angle method with TTY bolts, the arguments began

[/quote]

Pretty sure they are TTY when done with the revised method. Any bolt is tty if you go far enough

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Re: torquing down 16v head

Why is this so complicated. You torque the head bolts down to the OEM recomendation. You cant go more or else you will stretch the bolt.

Doesnt matter what gasket you use.

The only time you can change the torque value is whne using ARP studs. Guys go a little further with the ARP recomendations to get more clamp force to stop heads from lifter using high boost applications.

Doesnt matter what gasket you use.

The only time you can change the torque value is whne using ARP studs. Guys go a little further with the ARP recomendations to get more clamp force to stop heads from lifter using high boost applications.

1988 Toyota Levin GTZ 410kw atw @26psi

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

Join us on facebook - MRP - Manon Racing Products

http://www.mrpltd.co.nz

Turbonetics|Fortune Auto Coilovers|Wilwood brakes|Tilton clutches|

-

Bazda - Toyspeed Sponsor

- Posts: 5713

- Joined: Sat Jun 01, 2002 10:32 pm

- Location: Auckland

Re: torquing down 16v head

Bazda wrote:Doesnt matter what gasket you use.

Glad you dropped in Because you are someone who will probably have

all the stuff lying around to put an end to this discussion. All I need to know

is what torque you end up with when you put a MLS gasket on a 16V 4AGE

and tighten it using the OEM recommendation of 22 ft-lb + 90 + 90.

If you have an old MLS gasket and a dead 16V in the back of the workshop,

you could become world famous in New Zealand

Cheers... jondee86

1984 AE86 Corolla GT Liftback, NZ new... now with GZE

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

-

jondee86 - Toyspeed Member

- Posts: 903

- Joined: Mon Aug 18, 2003 11:08 pm

- Location: Wellington

Re: torquing down 16v head

There is no point in Bazda wasting his time (if he even has the right gear) to figure out how much torque it takes to do the +90 +90 step.

A more useful test would be to get some new head bolts, measure them accurately, then torque down a head with 22 +90 +90 process and remove bolts and measure to confirm or not that they have changed in length. That would confirm whether they are being used as a TTY bolt, or if toyota used the angle method simply as it is a far more accurate way of getting the right preload in the bolts.

A more useful test would be to get some new head bolts, measure them accurately, then torque down a head with 22 +90 +90 process and remove bolts and measure to confirm or not that they have changed in length. That would confirm whether they are being used as a TTY bolt, or if toyota used the angle method simply as it is a far more accurate way of getting the right preload in the bolts.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Re: torquing down 16v head

There is no problem is following the manufacturers instructions when replacing

an OEM head gasket with the same type of OEM gasket, and using OEM bolts.

The problems arise when people start changing stuff around. There is a huge

amount of confusion about whether the OEM head bolts on certain engines are

TTY or not ? Many people automatically assume that any head bolt tightened

using the torque-angle method will be TTY. This is despite the fact that the FSM

may provide length measurements for determining if the bolt is suitable for re-use.

And some comments on one way of figuring out if you are working with TTY bolts

or TAT (torque-angle-tighten) bolts...

And lastly but by no means of least importance, is the question of should TTY

bolts be installed dry or lubricated....

Trying to get a better understanding of the HOW and WHY of engineering matters

is never a waste of time. There is almost always two ways of doing anything... the

right way and the wrong way. Knowledge helps to bring the odds in your favour

Cheers... jondee86

an OEM head gasket with the same type of OEM gasket, and using OEM bolts.

The problems arise when people start changing stuff around. There is a huge

amount of confusion about whether the OEM head bolts on certain engines are

TTY or not ? Many people automatically assume that any head bolt tightened

using the torque-angle method will be TTY. This is despite the fact that the FSM

may provide length measurements for determining if the bolt is suitable for re-use.

Cylinder Head Installation For 1999-2006 Chrysler/Jeep 4.7L VIN J & N Engines

The cylinder head bolts on 1999-2006 Chrysler/Jeep 4.7L VIN J & N engines. are tightened

using a Torque-To-Angle procedure commonly referred to as TTA. Even though the cylinder

head bolts are tightened using torque and an angle procedure, the bolts are not a

Torque-To-Yield TTY, which are a single use design.

Therefore,TTA bolt re-use is possible if each bolt is “qualified” (examined for neckdown) first.

If the threads are necked down, the bolts should be replaced. One method of checking for

neck-down is to use a like-size nut and check to make sure you can easily thread it along the

entire threaded area of the fastener. Once reuse or replacement is determined, follow the

steps listed below to install the cylinder heads for these engines.

1) Clean the cylinder head and cylinder block mating surfaces.

2) Position the new cylinder head gasket on the locating dowels.

When installing cylinder head, use care not to damage the tensioner arm or the guide arm.

3) Position the cylinder head onto the cylinder block.

Make sure the cylinder head seats fully over the locating dowels. Note: The four smaller

cylinder head mounting bolts requiresealant to be added to them before installing. Failure

todo so may cause leaks.

4) Lubricate the cylinder head bolt threads with clean engine oil and install the ten M11

bolts finger tight.

5) Coat the four M8 cylinder head bolts with Mopar Lock & Seal Adhesive (or aftermarket

equivalent), and then install the bolts finger tight.

6) Tighten the bolts in sequence shown above in Figure 4, using the following steps and

torque values:

1) Tighten bolts 1-10, 15 ft. lbs. (20 Nm).

2) Tighten bolts 1-10, 35 ft. lbs. (47 Nm). Tighten bolts 11-14, 18 ft. lbs. (25 Nm).

3) Tighten bolts 1-10, 90°. Tighten bolts 11-14, 22 ft. lbs. 30 Nm).

And some comments on one way of figuring out if you are working with TTY bolts

or TAT (torque-angle-tighten) bolts...

The biggest reason that most [myself included until recently] consider the

new style bolts to be TTYs is the appearance of the bolt itself: it has the

reduced diameter section between the head and the threads. Combine the

appearance with the angle tightening and the reasonable conclusion to be

drawn is that they are indeed TTYs.

BUT, there is one very important thing that needs to happen when tightening

down a TTY bolt that does NOT happen when tightening down the new style

bolts on a Volvo redblock: the YIELD.

In all the motors on which I have tightened down the new style bolts,

following the factory procedure [15 lbs-ft, 45 lbs-ft, angle tighten 90

degrees], I have never felt the bolts yield. And when a bolt yields, you CAN

feel it. It feels like you have started to pull the threads. I have

overtightened bolts on other things; I KNOW the feeling of the yield.

The new style bolts are NOT TTYs; they are TATs.

And lastly but by no means of least importance, is the question of should TTY

bolts be installed dry or lubricated....

The use of a lubricant under the bolt head and threads, as mentioned, will alter

the torque rating substantially, and should be used if recommended by the bolt

or engine manufacturer. This fact is often overlooked and a wet torque specification

is used with a dry bolt, resulting in a lack of clamping force; if a dry specification

is used wet, the exact opposite will occur. The bolt will now be over-torqued,

with possible internal damage from entering its plastic range.

Trying to get a better understanding of the HOW and WHY of engineering matters

is never a waste of time. There is almost always two ways of doing anything... the

right way and the wrong way. Knowledge helps to bring the odds in your favour

Cheers... jondee86

1984 AE86 Corolla GT Liftback, NZ new... now with GZE

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

-

jondee86 - Toyspeed Member

- Posts: 903

- Joined: Mon Aug 18, 2003 11:08 pm

- Location: Wellington

Re: torquing down 16v head

jondee86 wrote:There is no problem is following the manufacturers instructions when replacing

an OEM head gasket with the same type of OEM gasket, and using OEM bolts.

The problems arise when people start changing stuff around. There is a huge

amount of confusion about whether the OEM head bolts on certain engines are

TTY or not ?

If the torque procedure is specified as torque+angle and there is any doubt just replace the bolts, they are cheap enough to not even think about it.

There is no problem with changing things around, its REALLY simple. If using OEM bolts, use OEM torquing procedure. If using Aftermarket bolts/stud use their procedures.

Cometic says use bolt manufacturers specs

Chrysler/Dodge tsb, use same spec for MLS as composite

I checked the 3s engine manuals,. Same bolts, same torque on gen2 and gen3 engines, even though gen2 used composite gasket, and gen3 used MLS.

Three different sources that should know wtf they are talking about, all saying the same thing.

How hard is this to understand????

And lastly but by no means of least importance, is the question of should TTY bolts be installed dry or lubricated....

Er, whatever it says in the bloody manual!!!! (which has always been lubed in every manual i've looked at, maybe lawnmowers or tractors or something have dry install head bolts?)

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Re: torquing down 16v head

So I guess what you are saying is that you don't actually know what torque

I would finish up with if I installed a TRD 0.8mm MLS gasket on a 16V 4AGE

using lube on the bolts and the 22 ft-lb + 90 + 90 FSM recommendation ?

Simple enough question... surely someone must have checked it ?

Cheers... jondee86

I would finish up with if I installed a TRD 0.8mm MLS gasket on a 16V 4AGE

using lube on the bolts and the 22 ft-lb + 90 + 90 FSM recommendation ?

Simple enough question... surely someone must have checked it ?

Cheers... jondee86

1984 AE86 Corolla GT Liftback, NZ new... now with GZE

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

-

jondee86 - Toyspeed Member

- Posts: 903

- Joined: Mon Aug 18, 2003 11:08 pm

- Location: Wellington

Re: torquing down 16v head

If you understood why they went to torque+angle you would know that your question is meaningless as there is a huge range of answers to the question. All correct, but also all wrong.

If you want a number, you need to put a torque gauge on the end of your powerbar and point a video camera at it while tightening a head bolt to 22+90+90 then play the video back to find "the number". (or use a strain gauge setup and a datalogger)

Then you get a new headgasket, a set of new head bolts, torque them up to 22ft.lbs, put the paint dot on them facing forward, then continue tightening them with your torque wrench set to "the number", and then you end up with paint dots facing in several different directions, (maybe you get lucky and some are facing rearwards) and a head gasket that'll be prone to failure because the bolts weren't properly tightened to the correct preload.

http://www.enginebuildermag.com/2001/02/threaded-fasteners-torque-to-yield-and-torque-to-angle/

If you want a number, you need to put a torque gauge on the end of your powerbar and point a video camera at it while tightening a head bolt to 22+90+90 then play the video back to find "the number". (or use a strain gauge setup and a datalogger)

Then you get a new headgasket, a set of new head bolts, torque them up to 22ft.lbs, put the paint dot on them facing forward, then continue tightening them with your torque wrench set to "the number", and then you end up with paint dots facing in several different directions, (maybe you get lucky and some are facing rearwards) and a head gasket that'll be prone to failure because the bolts weren't properly tightened to the correct preload.

http://www.enginebuildermag.com/2001/02/threaded-fasteners-torque-to-yield-and-torque-to-angle/

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

Re: torquing down 16v head

The early 4AGE FSM called up 43 ft-lbs in three passes, which changed in the

later (1987) version of the FSM to 22 ft-lbs + 90 + 90. And there was no change

to the bolts. So one could assume that the torque-angle method was calculated

to achieve the same (or possibly higher) clamping load as the specific torque

method when using the OEM composite gasket.

What is not known is whether the bolt goes beyond the elastic limit and into

the plastic region. Of if you like, how much torque can the bolt handle before

it gets into the plastic region ? If the bolt is not designed as a TTY bolt, but

is torqued past the elastic limit, plastic deformation is most likely to occur in

the threads, or the bolt may break at the first thread.

Since as far as I know people have been happily re-using 16V head bolts for

many years, is bolt deformation or breakage a common occurrance ? Or more

specifically, does it happen more often when installing TRD MLS gaskets ?

Cheers... jondee86

later (1987) version of the FSM to 22 ft-lbs + 90 + 90. And there was no change

to the bolts. So one could assume that the torque-angle method was calculated

to achieve the same (or possibly higher) clamping load as the specific torque

method when using the OEM composite gasket.

What is not known is whether the bolt goes beyond the elastic limit and into

the plastic region. Of if you like, how much torque can the bolt handle before

it gets into the plastic region ? If the bolt is not designed as a TTY bolt, but

is torqued past the elastic limit, plastic deformation is most likely to occur in

the threads, or the bolt may break at the first thread.

Since as far as I know people have been happily re-using 16V head bolts for

many years, is bolt deformation or breakage a common occurrance ? Or more

specifically, does it happen more often when installing TRD MLS gaskets ?

Cheers... jondee86

1984 AE86 Corolla GT Liftback, NZ new... now with GZE

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

spec small port, twinscrew s/c and water/methanol injection

Watch this space >>> <<<

-

jondee86 - Toyspeed Member

- Posts: 903

- Joined: Mon Aug 18, 2003 11:08 pm

- Location: Wellington

Re: torquing down 16v head

jondee86 wrote:What is not known is whether the bolt goes beyond the elastic limit and into

the plastic region.

Which is what I suggested testing earlier. Measure a new bolt set, torque em up, remove them and remeasure.

Of if you like, how much torque can the bolt handle before

it gets into the plastic region?

Still a meaningless question. Bolts dont handle torque, they handle stress, and its a complex relationship with several variables between them.

Reality: A nasty hallucination that is caused by excess blood in the alcohol stream.

- Grrrrrrr!

- Toyspeed Member

- Posts: 2566

- Joined: Tue Jun 17, 2003 7:21 pm

- Location: Souf Orkland

23 posts

• Page 1 of 2 • 1, 2

Who is online

Users browsing this forum: Bing [Bot], Google [Bot] and 21 guests