don't you hate it when you start making good progress on something, and then decide you're not happy with it?

after my last post on this I had been thinking about the flow through the duct from the radiator to the vent. At one point the cross section was getting quite small, and I was doubting whether it would flow enough to make all this hard work even worthwhile...

so I decided to make some changes. I didn't want to cut the hole any higher, because I was trying to keep the reinforcing piece that runs along the top of the bulkhead, but I decided that it just had to go.

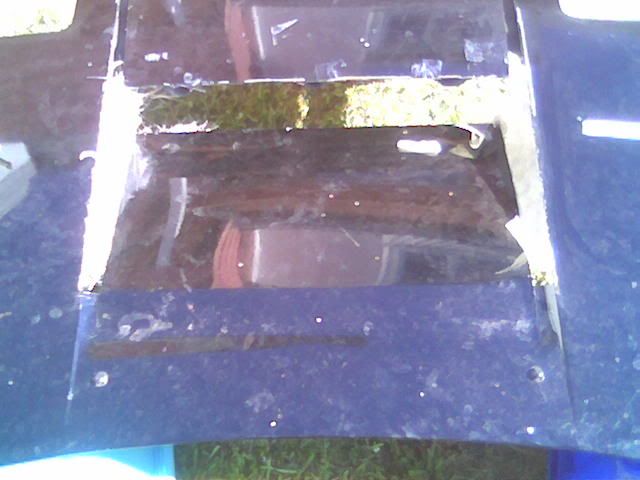

So, here's the new hole:

Now I had to do something about reinforcing everything, so I decided to make a frame, using 19.1mm 1.2mm wall thickness square section tubing.

This frame will be welded in place as shown. It will give a lot more strength to the area, and so it wont rely on welded steel panels for strength like I had originally planned. This means I could rivet or bolt the ducting on for easier removal, and I can make more use of fibreglass to minimise weight.

Anyway, because hole in the bulkhead is now much larger the shrouded piece I had made before needs modifying. I cut the top piece off, and will make a fibreglass top for it, which will seal against the frame I made.

Here's the shroud, the second picture shows where the fibreglass panel will sit

as you can see in this picture, the area for air to flow through is now greatly increased.

The other ducting I made earlier for inside the frunk will be kept, but altered to fit to the frame, rather than to be welded together.