All ready to go into the new shell tomorrow after work.

Wouldnt you want the drain to be as high as possible? I could see that causing you some problems in that position due to the sumps oil level stopping the oil draining.

Moderator: The Mod Squad

siren676 wrote:Yeah just threaded in there, 1/2" BSP taper thread, so seals on itself as its wound in

siren676 wrote:Didnt have any proper loctite at the time so its just thread taped in there, sump is aluminum not steel which is why its not welded in

siren676 wrote:Didnt have any proper loctite at the time so its just thread taped in there, sump is aluminum not steel which is why its not welded in

Any plumbing workshop will have them as well as they usually come on 1/2" ballcocks. And it's called a parallel not flat thread - just so you're asking for the right thing. You might also have to be conscious of electrolytic action between the brass and the aluminium sump. Can't remember which one will be sacrificial.....sergei wrote:siren676 wrote:Didnt have any proper loctite at the time so its just thread taped in there, sump is aluminum not steel which is why its not welded in

Get something like this:

Preferably on both sides.

Any decent engineering or fastener shop should have them. Ask for 1/2" BSP Flanged Back Nut.

Preferably to get them in brass, but steel will also work, although for steel you will definitely need to locktite it.

Edit: I saw it is tapered thread, so if you are going to put flanged nuts on both sides (which is better than tapered thread) get a fitting with flat thread. It will cost you at most $20 for 2 nuts and a new fitting, but it is a better solution. The best solution is to weld an alloy fitting on there.

siren676 wrote:Bit too late now, sump is on and engine is back in the car.

A lot of mx5 people have done it this way and not had problems.

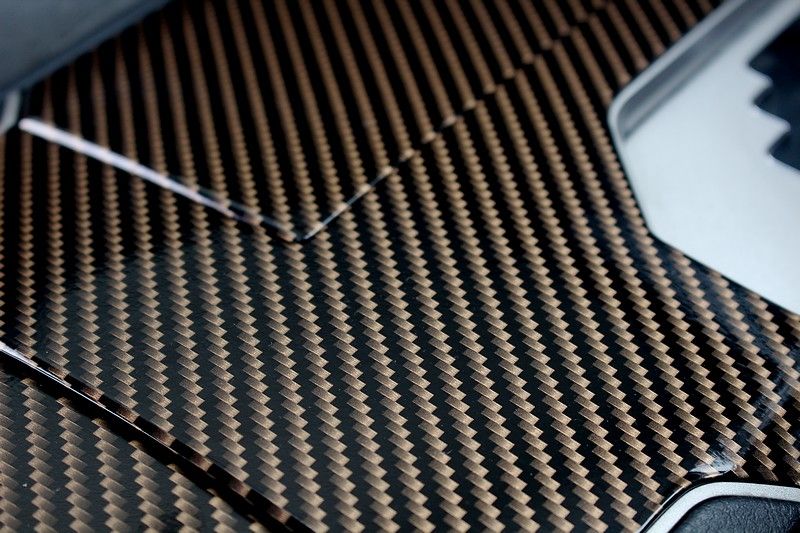

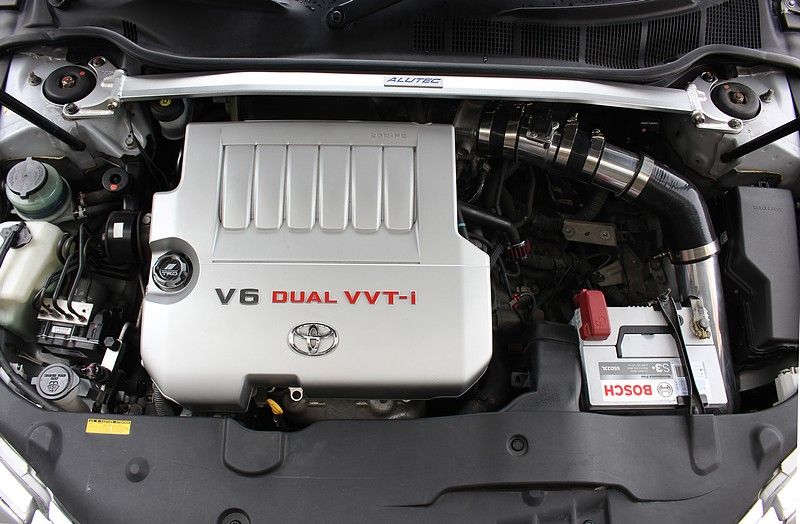

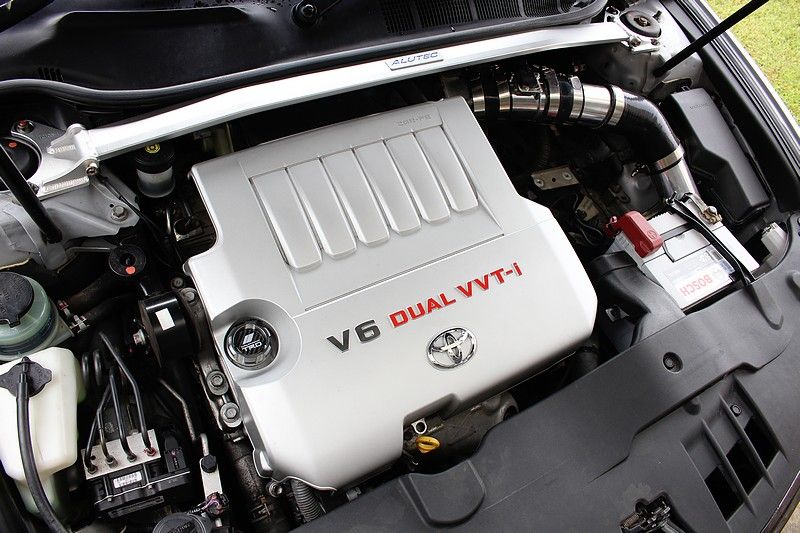

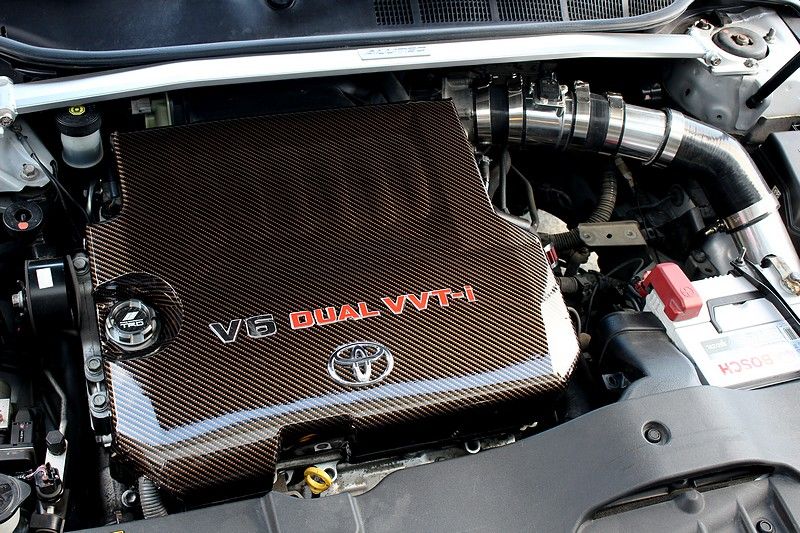

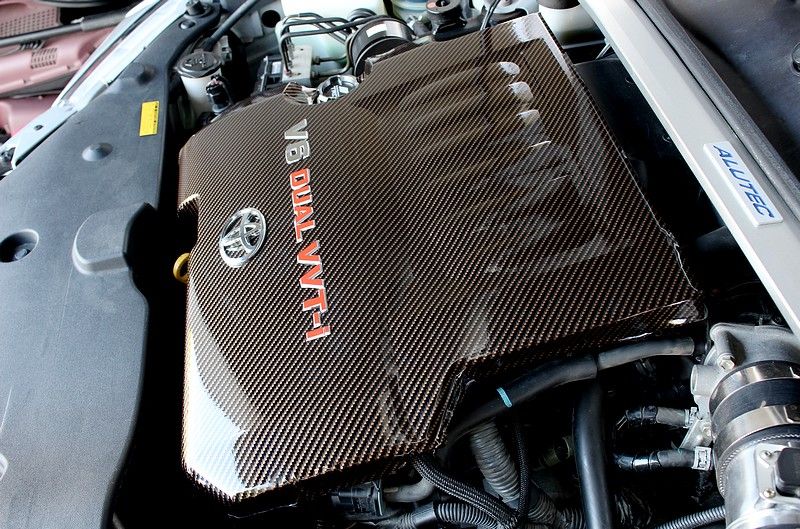

Kiwi-Corolla wrote:With a few more hours of daylight left, I decided it would be interesting to wrap one of my spare engine covers (and here I was thinking the center console was a challenge, haha). This is the finished result:

Quint wrote:Not just cock, large cock.

Return to General Car Discussion

Users browsing this forum: No registered users and 26 guests